How to create an organoid bioreactor (and how to market it): Interview with Dr. Bart Spee

“It’s a big deal, but you might be underwhelmed when you see the actual device” is not the best sales pitch for a something tantalisingly named an “organoid bioreactor”. But looks can deceive. The small device that Dr. Bart Spee developed can mean big things for the pharmaceutical industry. The device he developed as part of his research for Utrecht University dramatically improves the efficacy of cell cultures used in drug research. The spinning bioreactor produces miniature organs (organoids), used to test various substances on human tissue. Now Dr. Spee is spinning out his product to the market, learning new skills as he goes.

Our organoid bioreactor produces organoids five times faster and mimic organ function better than organoids grown by traditional methods

Over the past decade, major strides have been made in organoid research and application. These 3D structures of human or animal tissue grown from stem cells are broadly used in both fundamental and applied research. They play a crucial role in drug discovery and safety and are very effective at testing the efficacy of substances on human tissue. It is no wonder that both industry and academia are looking for ways to improve the production process of organoids. “Our organoid bioreactor produces organoids five times faster and mimic organ function better than organoids grown by traditional methods” says Spee with a touch of pride. His invention stems from his own experiences with organoid culture, which is, in his own words: tedious and hard to standardise. “Organoids are traditionally grown in 3D hydrogels such as Matrigel. We found out that when you put organoids into a suspension and spin them around in a bioreactor, the cells proliferate much faster”, he explains. Simply put: spinning gives the cells easy access to oxygen and nutrients they need to grow. “It was a simple equation for us: we can produce more cells with better performance, the market needs this.”

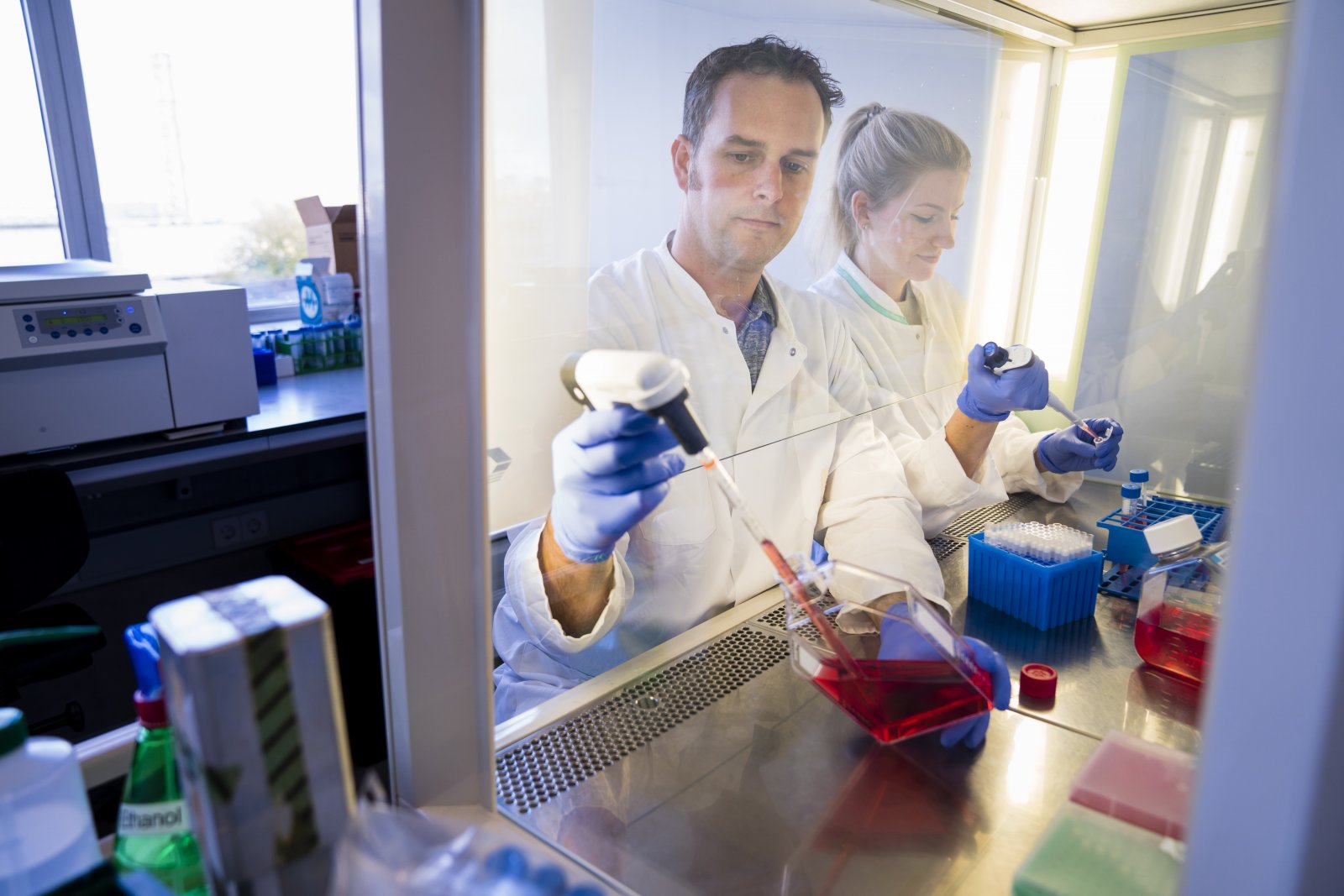

The team consisting of Bart Spee and postdoc researcher Kerstin Schneeberger quickly found out that their spinning bioreactor produced the same sorts of cells that are normally grown in gels, but much faster and that they mimic organ function much better. The cyst-like structures which the bioreactor produces are very efficient for various toxicological tests. “Many drugs fail in human trials after successfully being tested on animals, simply because humans have a different metabolism. Our in-vitro test with human liver cells can better predict liver toxicity.” Having better-functioning cells results in in-vitro models that can substantially reduce the need for animal testing. The tissue the team uses to culture organoids comes from rest material a transplant unit at the Erasmus Medical Center or directly from patients allowing ‘personalized medicine’ approaches. Human liver cells can be cultured for a long time and can differentiate into various cell types (hepatocytes and cholangiocytes). These cell cultures are used for testing human drugs, this is the type of technology that the industry needs.

While we were developing the bioreactor, we always kept in mind the potential market value

“While we were developing the bioreactor, we always kept in mind the potential market value. We knew our way to the technology transfer office quite well. Patenting or licensing our product was always on our mind. Especially because valorisation aspects of research are becoming more and more important in grant applications”, Spee explains. But now that there’s a real product, the researchers are on a journey to become entrepreneurs. “The spinning bioreactor outperforms the competition when it comes to organoid production, so the market potential is clear. And if there is no competition, there is no market: that’s just one of the things we are learning in an intensive entrepreneurship course at UtrechtInc, a startup incubator” says Spee. The entrepreneurship journey started during the summer after a meeting with Stephen Gray of ROM Region Utrecht and Utrecht Science Park. “I knew Stephen through the UAIM Hub so we’d chatted before about startups and spin-outs and the like. Stephen really showed me the commercial potential of the organoid bioreactor technology. He took me through the steps of starting our own startup venture and explained how to de-risk the process associated with biotechnology startup formation from his own experiences and lessons learned in the industry, highlighting the importance of thinking beyond the technology." It was very lucky that we spoke about our bioreactor when we did, because we later got accepted into the UtrechtInc validation course just in time. A quick pitch and application later, Spee and Schneeberger were was admitted into the program. “They must have seen potential in our product and likely they saw our lack of experience as entrepreneurs”, Spee laughs. “We are now in week 3 and it’s pretty intense. You learn all the basics of becoming an entrepreneur in a really short time”

“It is not in my nature to keep things to myself”, says Spee, who is a firm believer of open science. “However when you are developing something novel with real market potential, that’s something you also want to protect.” The team developed the bioreactor outside of the academic spotlight as much as possible. “The bioreactor was not part of a PhD project for it would have been hard to ask a PhD not to publish, and even Masters students who wrote their thesis on the subject now have their thesis under embargo.” In the end, the aim is to spin the product out and get it running in as many labs as possible. “We know there’s interest, the bioreactor is already running in colleagues’ labs under non-disclosure agreements”. Spee would love to present his product at an academic conference, but he will have to wait for the patent before he can do that.

“The first bioreactor we built was really trial and error” Spee recalls while he pulls up a video of the device as it is now. “Literally everything was either 3D printed or fabricated by the Utrecht University workshop. We even ordered some ready-made components online”. It may not look like not much, but the intellectual property is in the design and the specific protocols that can ultimately be reproduced in a more industrial fashion. The specific blade configuration and shape of the propellers, the spin speed and the mixing protocol, these are all ready to be produced on a larger scale when the patent is in place. “We are experts in liver tissue, but we already have the ability to reproduce various types of organoids such as kidney and intestinal organoids. All of these require slightly different protocols which we can develop, but we’ll need to scale up for that, become real entrepreneurs”, quips Spee, who is now learning the ropes of entrepreneurship at UtrechtInc. If it comes to a real business, Spee will share the revenue with Utrecht University, where he developed the bioreactor.

So how do you sell a product like a spinning bioreactor? “Our customers are basically ‘us’ but then in different labs. So we can convince them with the science. That can become technical rather quickly so it’s a challenge for us to explain the bioreactor in layman’s terms”. Potential customers will likely already be familiar with spinning bioreactors, which are used in different contexts. “We have developed a product that has a proven track record with organoid production, so that will be our angle. It’s much more than a simple blender”. The valorisation course at UtrechtInc is a real journey for Spee, who is discovering his entrepreneurial side here. “The skills I get out of this will be useful no matter the outcome of the spin out”, he says. Part of Monday’s course was the elevator pitch. “It’s still rough, but here goes:

“As we all know, organoid culture is tedious and difficult to standardize. We have developed a novel spinning bioreactor that you can easily implement in your own lab. With our organoid bioreactor you will standardise your culture and increase your yield fivefold. Moreover, your organoid will function up to 60% better when using the bioreactor, at a fraction of the price. If you want less cost and a less labour-intensive organoid culture, ask for a demo in your lab.”

The bigger picture

The EU project ‘organtrans’ has ambitious aims for 3D-biofabrication, with an ultimate goal of printing an entire human liver. When only taking into account the main cell-type of the liver, the hepatocytes, that would require the production of over 150 billion cells. On traditional growth media, that would mean a couple of labs full of cell-cultures. To increase cell production, spinner flasks were considered, as these are already used to produce other types of cells. In Utrecht we put this into practice and are now forerunners in this field.

The ROM Regio Utrecht are working together with Utrecht Science Park, and Utrecht Inc to boost the business climate in Utrecht in the sectors of health, digital, and sustainability (start-ups, SMEs, and scale-ups). Within the health sector, they are actively working with the scientific professionals and academics within Utrecht Science Park to transform their innovative technologies into start-up ventures and spin outs within the growing fields of biotechnology, life sciences, and regenerative medicine.